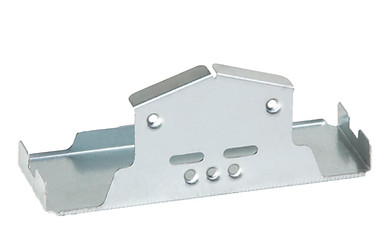

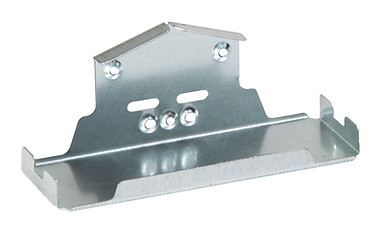

Home Appliance Interior Support

With our proven expertise in mass production of high quality components, a client in the home appliance industry contracted with HRB Industries Corporation to manufacture the interior supports shown here. From the outset, we clearly saw the need to develop a highly precise and automated manufacturing strategy to meet the volume requirements. With production quantities reaching from four to five million units per year, we needed throughput rates on the order of 15,000 to 18,000 parts on a daily basis to fulfill the client’s orders on time.

We took the time up front to make a careful study of all aspects of this project. In addition to factors like part geometry, material of construction, and quality requirements, we considered production methods and their compatibility with automation systems. As a full-service manufacturer, we also developed a material sourcing plan to ensure constant availability, as well as addressed packaging options that aligned with the client’s internal operations. Throughout the planning process, our cost engineer played an important role towards ensuring that economy was built into every phase of production.

To conquer the volume challenge, our process engineers designed a fully automated, high-speed progressive stamping process. At high volumes, progressive stamping is very economical. Our in-house team worked closely with various equipment vendors to build a work cell with integrated material feeders on the front-end as well as back-end packaging machinery that accommodated high velocity production. The heart of this production line consisted of a 160 ton press outfitted with precision built, easy to maintain tooling constructed from high-strength materials. Features such as in-process gage fixtures ensured that production remained consistent and accuracies were maintained, day in, day out, over the long term.

The quality, consistency, and yield rates on this production line were very impressive. We achieved an impeccable 0 ppm rejection rate on a part with ±0.005” dimensional tolerances on features as small as 0.10”. Our ingenuity in developing this production scenario significantly improved the cost profile of this component and saved the client measurable production costs.

If you are interested in learning more about our high volume manufacturing capacity,contact us today.